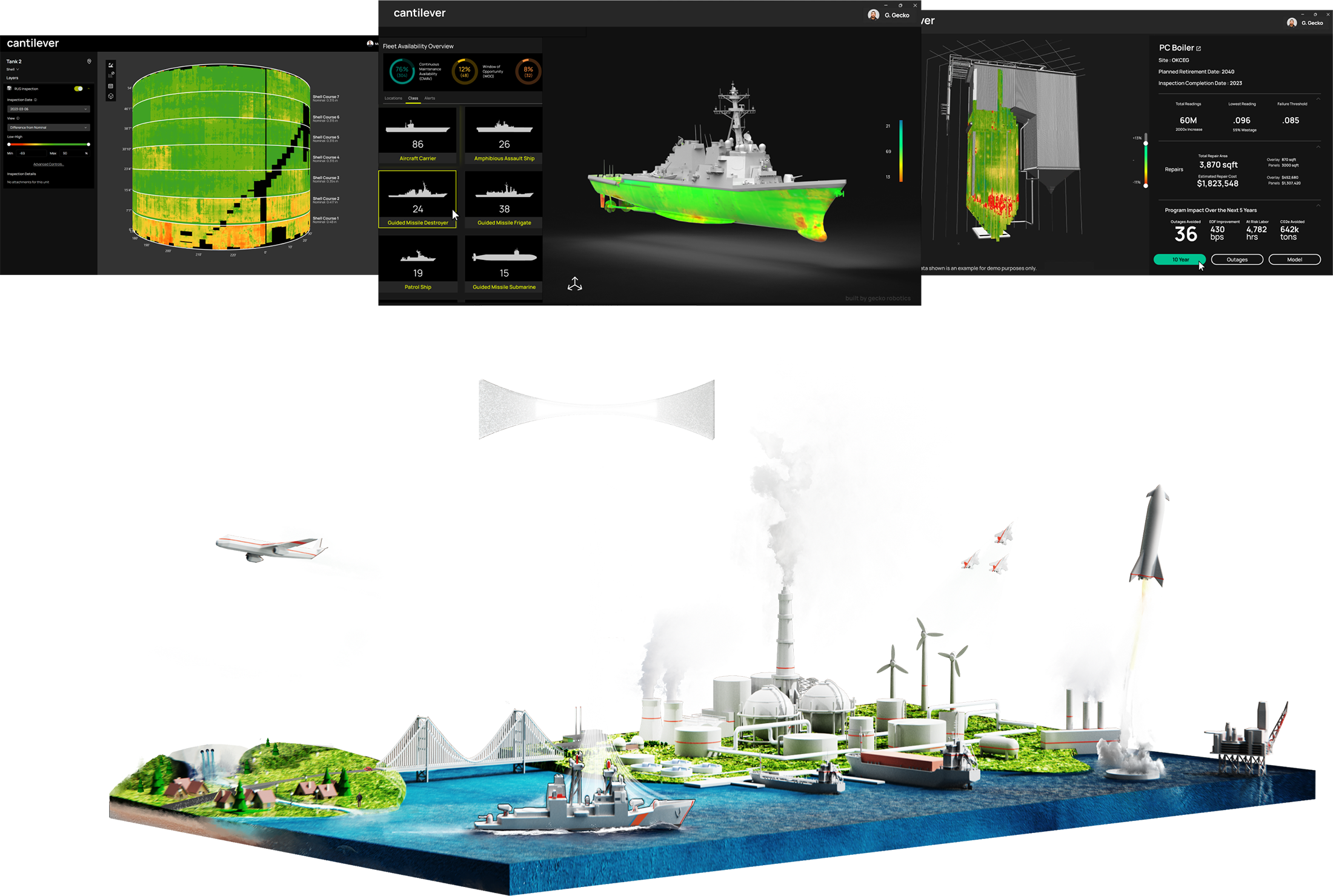

cantilever™

Bridging physical + digital

Cantilever™ integrates data layers from Gecko’s various robotic and hardware systems into a software platform that offers unparalleled insights into the operational availability of assets.

Modernizing your decisions

By bringing together data layers not previously possible, Cantilever is driving important decisions for customers that increase uptime, decrease costs, and reduce safety issues.

Data layers

A combination of robots, drones, and fixed sensors collect data, which is combined with historical health records, design files, operational data, and other business metrics to create Cantilever data layers.

Data systems

The data layers are processed through Cantilever’s AI-powered analysis engine to determine key insights.

Platform

The data is then imported into Cantilever’s software platform to empower customers to make targeted repairs, prioritize capital investments, and shift from reactive to predictive maintenance.

cantilever

Platform features

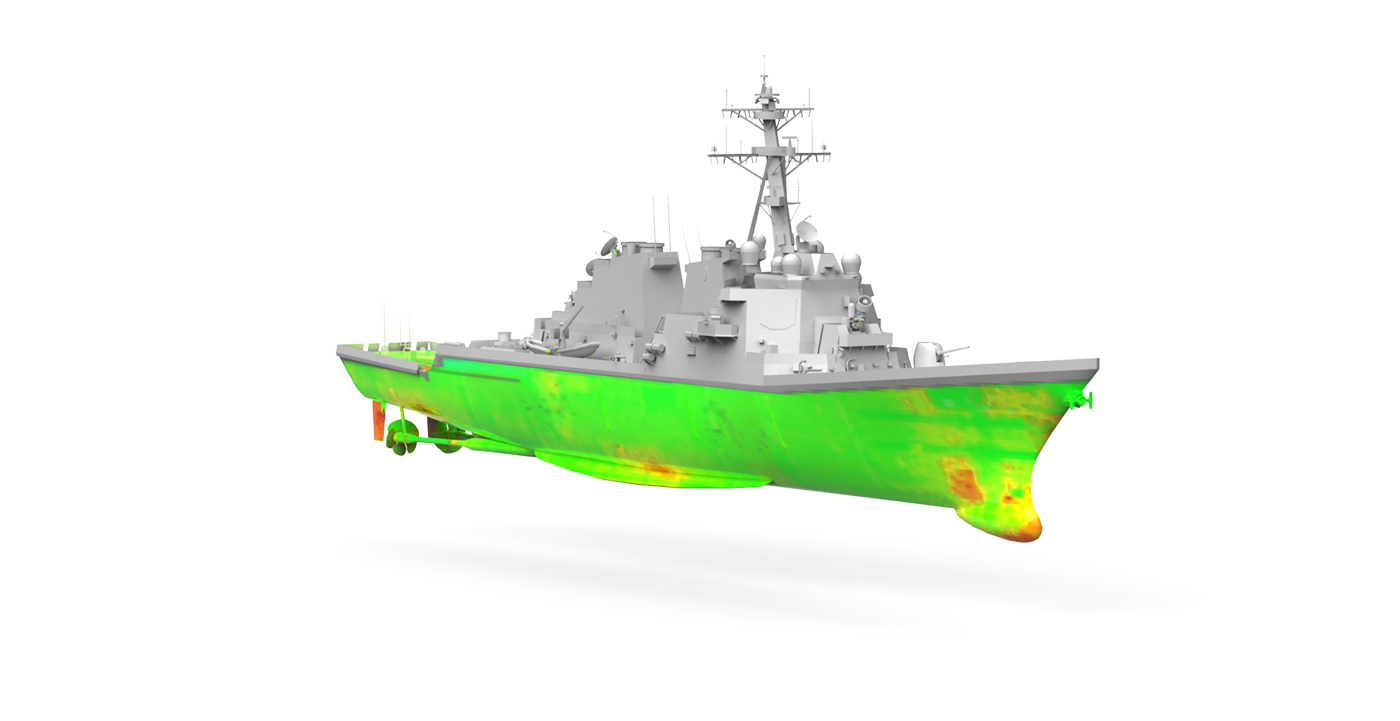

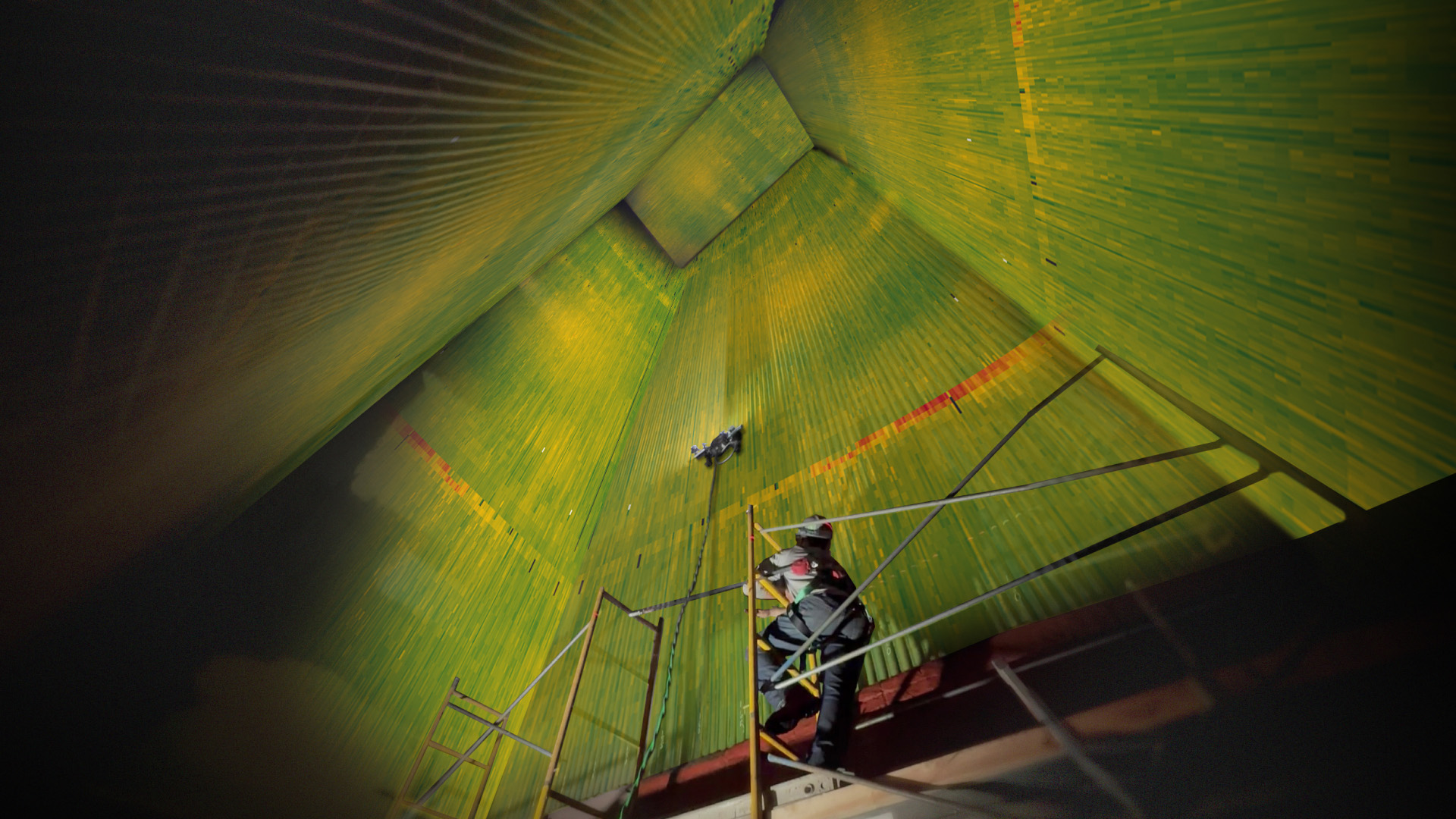

Availability

Forecast features interactive models for current and predictive asset health, including 2D and 3D color-coded corrosion maps and corrosion rate analyses to determine if the equipment is operational in its current condition.

Reliability

Turn to Asset Fix to improve the longevity of assets. Develop preventative maintenance plans based on asset health data, targeting areas needing immediate repairs and monitoring those that may progress to avoid failure over time.

Sustainability

Use Asset View to build configurable scenarios to determine the useful life of assets, adjust end-of-life dates, failure thresholds, capital costs, and time allocated for repairs to optimize operations and reduce resource expenditures.

Empowering Customers to Optimize Operations

”We are partnering with Gecko to drastically reduce forced outages. Until Gecko, we have not been able to accurately predict where our equipment is going to fail before it does. With Gecko, we can stop these outages from happening by making smarter repairs, which at the end of the day is what improves energy reliability and affordability for our customers.”

– Plant manager

Boilers Analyzed by Gecko

TWh Energy Lost Annually without Digitization

Years of Proven Experience in Power Industry

Case studies

Gecko is solving a global challenge that impacts businesses, the environment and humanity.

Manual vs. Automated Inspection Data

Data quality is the key to successful asset management. However, not all data is created equal.

Download this infographic to learn about the five characteristics of data quality and how manual inspection methods compare to robot-powered data collection.

Let's get started!

Fill in your details and we’ll get back to you to demo Cantilever™ for you.