Power Plant Digitalization Solutions

Data to reduce forced outages. Insights to optimize maintenance.

Eliminate Tube Leaks with Actionable Analytics

Work smarter and increase uptime with Cantilever™ – Gecko’s turnkey, data-driven solution that accelerates decision making at scale. Our process rapidly collects, integrates, and analyzes robust data layers to deliver actionable precision maintenance plans for today and predictive insights for tomorrow.

Empower your teams across all levels to see, understand, collaborate, and act on critical asset data to avoid unplanned outages.

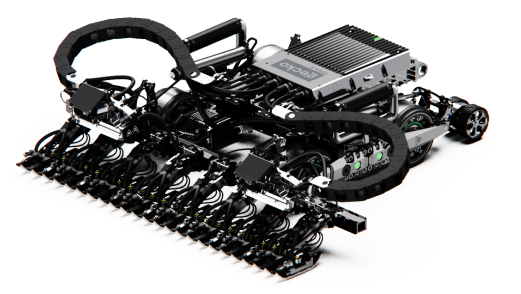

Gain Complete Visibility with Advanced Robotics

The first step in the Cantilever process is to collect complete, high-fidelity data layers of your assets. Our suite of automated robotic solutions performs non-destructive testing to build full-coverage, highly precise data layers that power our enterprise analytics tools.

Gecko’s robots collect 1,000x more data at speeds 10x faster than traditional methods. High-quality data coverage means confident next steps.

Millions of Data Points - Made Useful

Our industrial asset management software translates your data into actionable insights through comprehensive digital twins, predictive models, and repair plans. Cantilever Platform simplifies data to empower real-time decision making with current-state analysis and AI-powered predictive insights for your entire network of assets.

- Interactive 3D digital twins

- Predictive analytics

- Precision repair plans delivered within 24-48 hours of inspection

- One source of truth for all past, present, and future inspection data and repair records

Shift from reactive to predictive maintenance.

Solutions for All Power Plant Assets

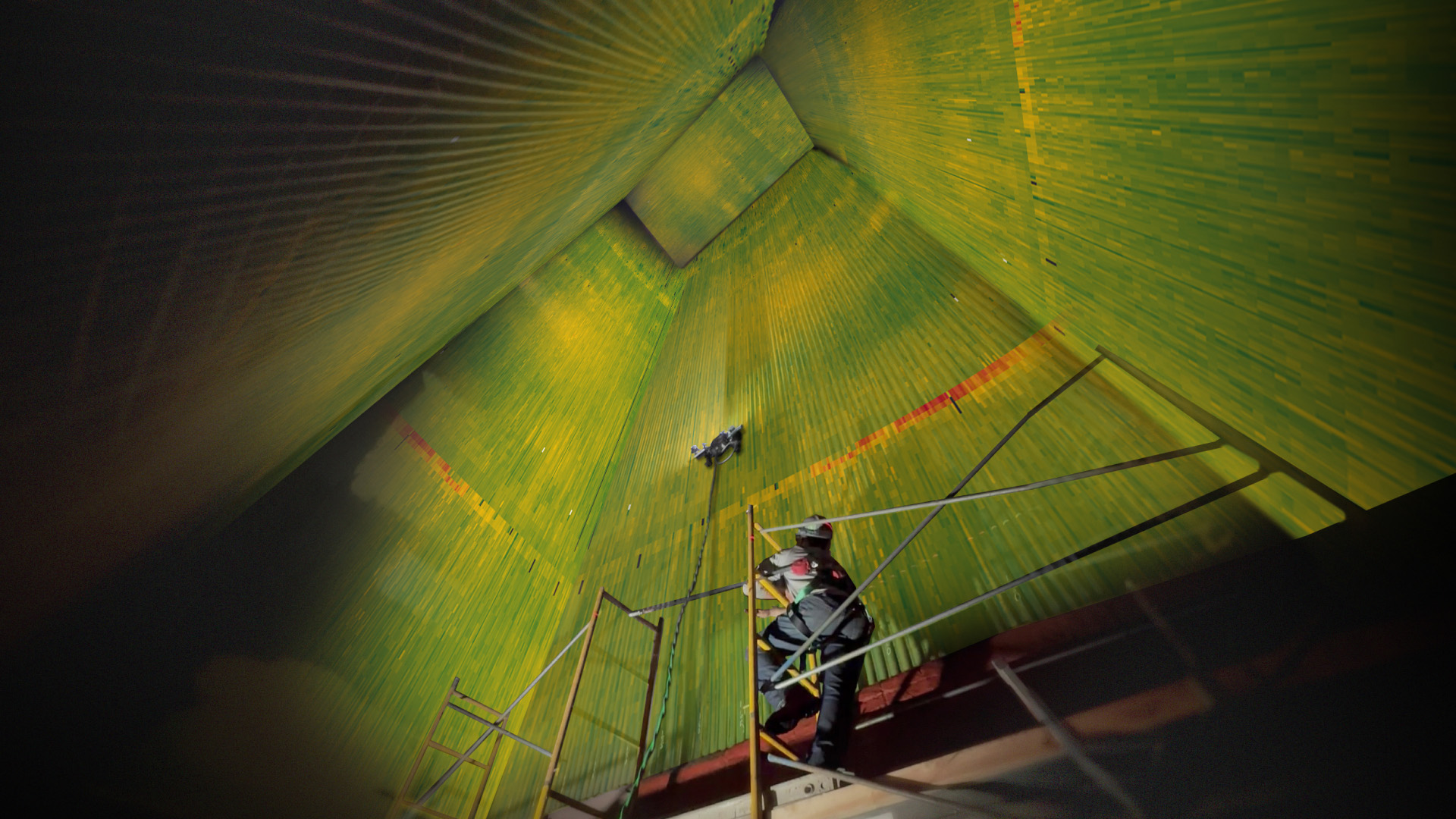

Boilers

Reduce forced outages and ensure consistent and reliable energy production through full coverage robotic inspection and data visualization of water wall tubes.

Scrubbers

Gecko’s corrosion mapping solutions pinpoints areas on the walls and cones of scrubbers where corrosion and erosion have caused wall thinning.

Silos

Avoid silo collapse, deformation, or other failure mechanisms that lead to shutdowns and injury through a comprehensive robotic inspection and software modeling.

Tanks

From the roof, shell, and floor, to everywhere in between, Gecko’s robotic solutions inspect in-service tanks, pinpointing areas needing repair and providing the data necessary for maintenance planning - including comprehensive API 653 assessments.

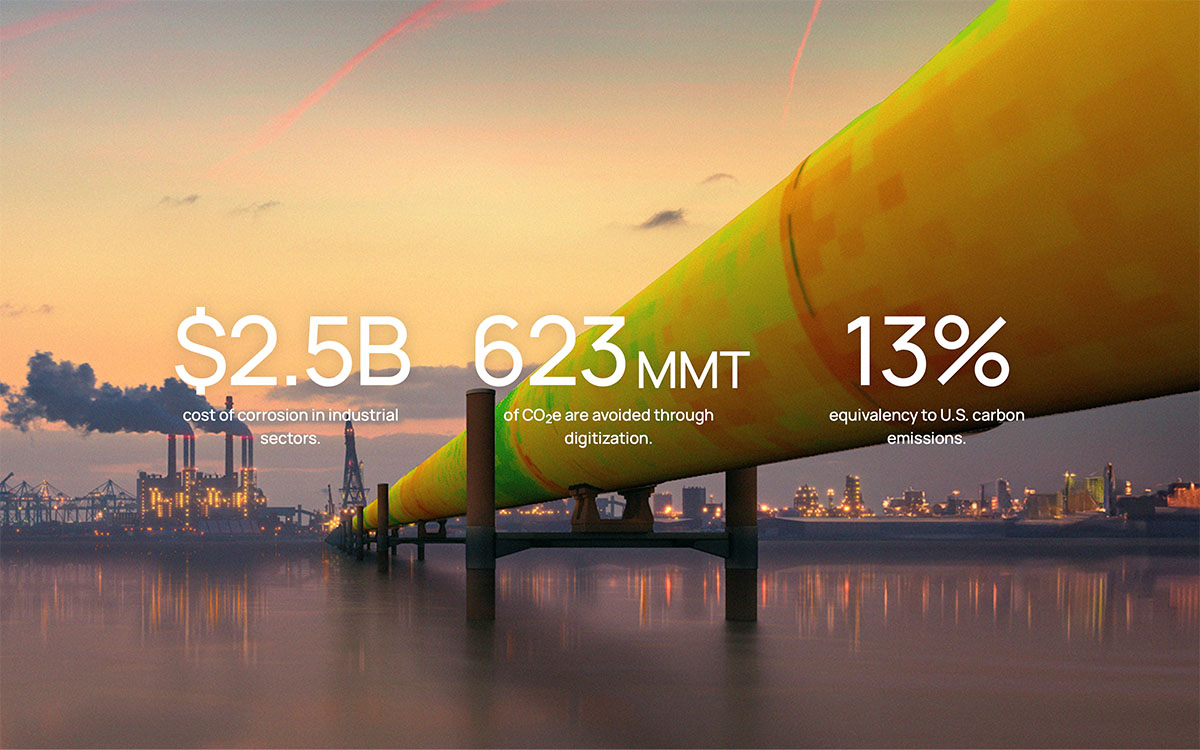

Transform Your Industrial Asset Management

Cantilever integrates Gecko’s high-fidelity data layers, historical records, process data, and in-house subject matter expertise into one system for unparalleled clarity.

Asset Management Applications to Achieve Your Goals

- Inspection Planning

- Digital Repository

- Repair Optimization

- Repair Prioritization

- Work Planning

- Budgeting & Planning

Customer Story: Boiler Maintenance Optimization

Discover how a power plant leveraged high-fidelity data analysis to proactively identify, prioritize, and fix 82 ft2 (8 m2) of damaged boiler tubes within its five-day planned outage. Our Cantilever solution helped the plant eliminate guesswork and increase the useful life of its boilers to reduce forced outages.

Empowering Customers to Optimize Operations

”We are partnering with Gecko to drastically reduce forced outages. Until Gecko, we have not been able to accurately predict where our equipment is going to fail before it does. With Gecko, we can stop these outages from happening by making smarter repairs, which at the end of the day is what improves energy reliability and affordability for our customers.”

— Plant Manager

Boilers Analyzed by Gecko

TWh Energy Lost Annually without Digitization

Years of Proven Experience in Power Industry

Transform into a Facility of the Future

Are you ready to optimize your asset management program? Complete the form to connect with one of our experts.

Gecko’s turnkey industrial asset management software is helping power industry leaders ensure seamless and sustainable energy production worldwide.