Tri-Lateral Phased Array

Superior Crack Detection

Tri-Lateral Phased Array (TriLat) is a revolutionary robotic ultrasonic testing method for the on-stream inspection of fixed equipment in caustic service.

TriLat identifies environmental cracking, including Hydrogen Induced Cracking (HIC), Stress Oriented HIC (SOHIC), and Sulfide Stress Cracking (SSC), and HTHA in carbon and low alloy steel equipment at unprecedented productivity and resolution.

Productivity

Covers 2.4 linear ft/min (0.7 m/min), up to 10x faster than conventional AUT depending on probe size.

Resolution

Over 150K UT readings per ft2 (1.6M readings/m2) are visualized through detailed A, B, C, and D scans.

Data Confidence

Positively identify laminations, inclusions, blisters, periphery cracking, and stepwise cracking.

Focalization

Passive and active focalization combine to identify damage at a depth of 4 inches (102 mm).

Temperature

Inspect in-service assets up to 240 degrees Fahrenheit (116 Celsius).

Inspectors

Inspection, data analysis, and damage identification are performed by ASNT Level III certified technicians.

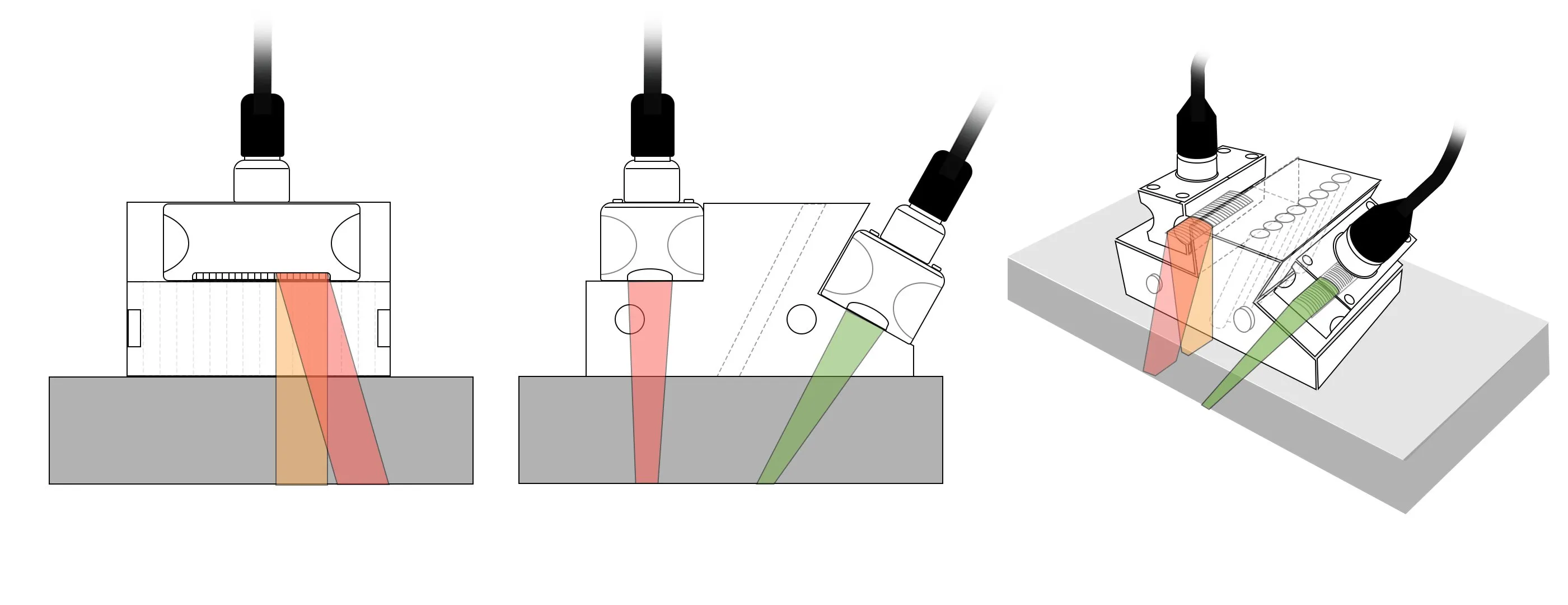

One Unit. Two Probes. Three Angle Beam Sets.

TriLat combines the power of two probes containing three total angle beam sets in one unit for unparalleled resolution to identify wet H2S damage at the earliest stages. One probe is set in a lateral configuration and the other is in a linear configuration. They are set at different skew angles and contain 64 element transducers each. The result is 128 elements firing with an electronic resolution of 0.024”x0.039”, which provides a data density that is 25x greater than conventional AUT.

Inspections with Tri-Lateral Phased Array are available immediately.

For more information, download the TriLat brochure or contact us today!