API 510 Pressure Vessel Inspections

Customizable and Comprehensive API Inspections

Whether you're undertaking a complete API 510 inspection on a time interval or looking to conduct just one portion of your Risk Based Inspection (RBI) program, Gecko’s services are tailored to your objective.

Our team of API inspectors specializes in deploying robotic inspection techniques and interpreting the data to provide comprehensive assessments and monitoring plans.

Records Review

The service and inspection history of the vessel is reviewed to deploy appropriate Gecko resources.

Serviceability Assessment

MAWP determination, T_min assessment, inspection intervals, remaining life, and corrosion rate determination.

Gecko Portal

All reports, alongside interactive data maps, are available online 24/7 for maintenance review and planning.

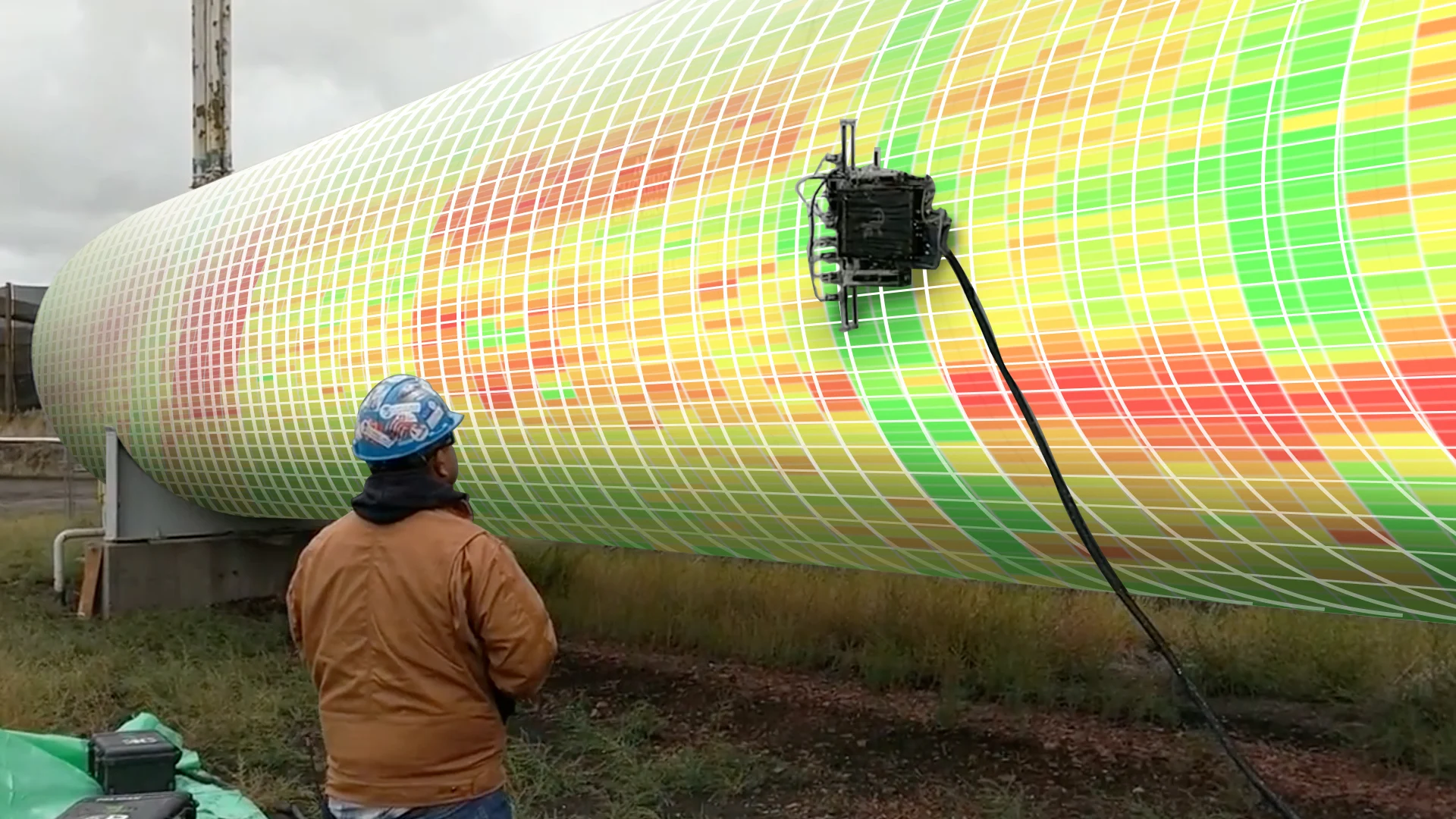

Rapid Ultrasonic Gridding

Complete ultrasonic gridding of assets to determine general wall thinning and map areas of corrosion.

Phased Array UT

Find defects in welds and heat-affected zones (HAZ) and perform high-definition corrosion mapping.

Visual Inspection

Identify any structural abnormalities, leaks, coating failures, or areas of concern for closer NDE.

More Coverage.

More Confidence.

Gecko Robotics' API 510 program is the most comprehensive and advanced inspection protocol in the industry. Unparalleled access to our NDE/NDT experts and complete asset coverage ensure our clients make superior reliability decisions.